| Item | Height | Length | Width |

| Size | 2600 | 4900 | 5200 |

| Item | Parameter |

| Rated capacity (KVA) | 440 |

| Power supply (V/φ/HZ) | 380/ 3 /50HZ |

| Primary current (A ) | 180 |

| Rated duty cycle (%) | 20 |

| Secondary empty voltage (V) | 10.4 |

| Throat depth (mm) | 270 |

| Cylinder stroke (mm) | 100 |

| Welding speed (s/piece) | 7 |

| Max. working pressure (kgf) | 1500 |

| Compresses air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption (0.5MPa air pressure, stroke: 60mm) (L/ welding spot) | 9.24 |

| Cooling water consumption (L/MIN) | 18 |

| Primary cable specification (MM2) | 3*50+2*16 |

| Max. Short Circuit Current (KA) | 30 |

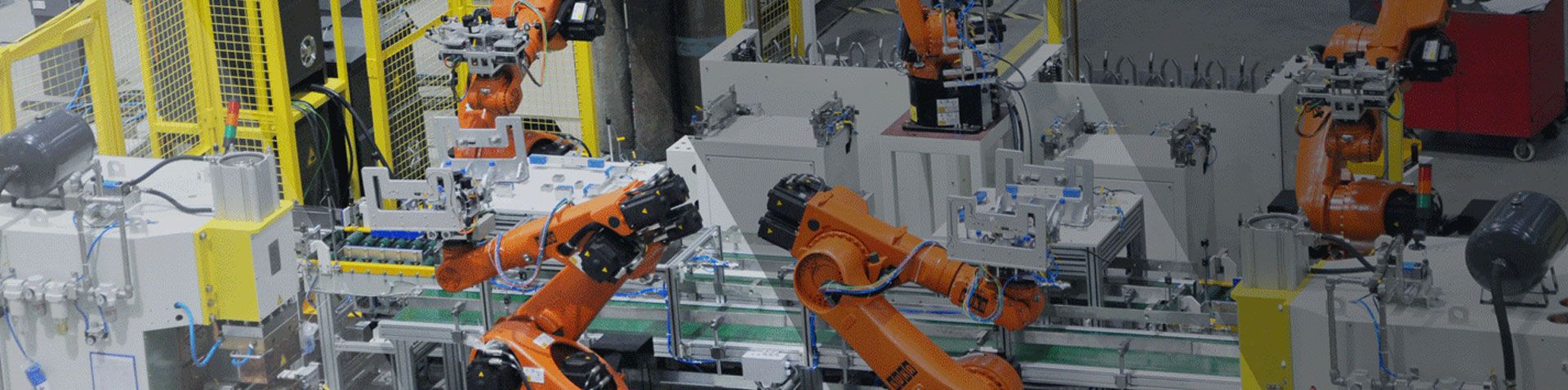

Feature of P4P type car seat rail automatic welding machine

1. The P4P type car seat rail automatic welding machine features a robotic gripping rail system and visualizer.

2. The car seat rail automatic welding machine is outfitted with a fully automatic medium frequency welding system and screw conveying system.

Background introduction of car seat rail automatic welding machine

The welder is specially developed for the manufacturing of Faurecia car seats. Our equipment can realize rail robotic gripping, automatic feeding, and automatic welding thanks to the introduction of our seat rail installation and other technology. The technology was created to realize fully-automatic smart manufacturing processes and to replace traditional stand-alone manual operation welding equipment.

| Item | Height | Length | Width |

| Size | 2330 | 2125 | 2600 |

| Item | Parameter |

| Rated capacity (KVA) | 2X165 |

| Power supply (V/φ/HZ) | 380/ 3 /50HZ |

| Primary current (A) | 240 |

| Rated duty current (%) | 20 |

| Secondary empty voltage (V) | 13 |

| Throat depth (mm) | 170 |

| Arm gap (mm) | 300 |

| Cylinder stroke (mm) | 70 |

| Electrode Dimensions (mm) | φ16X60 |

| Workpiece Dimensions (mm) | About 480*130*50 |

| Welding capacity (mm) | 2+2 |

| Welding speed m/min (s/piece)(time/s) | 24s/piece |

| Max. working pressure (kgf) | 400 |

| Compressed air pressure (MPa) | 0.6~0.7 |

| Compressed air consumption (0.4MPa air pressure, stroke: 30mm) (L/ welding spot) | 6 |

| Cooling water consumption (L/MIN) | 24 |

| XY axial driving motor power (KW) | 0.4;2 pieces |

| Primary cable specification (MM2) | 3*50+2*16 |

| Max. Short Circuit Current of transformer (A) | 30000*2 |

Feature of car seat side board spot and projection welding machine

1. The car seat side board welding machine features a double-station structure. After manual loading and clamping, the clamping equipment automatically rotates when the first procedure is fully completed.

2. Our welding machine is equipped with two medium frequency welding guns, which can move automatically and complete multipoint welding processes as set by the operator.

Introduction of car seat side board spot and projection welding machine

The car seat side board spot and projection welding machine is designed and produced to perform the automatic multipoint welding process of the side boards of car seat. It remedies the traditional problems of spot pitching and unstable quality caused by traditional single point welders.

| Item | Height | Length | Width |

| Size | 2550 | 5400 | 3900 |

| Item | Parameter |

| Rated capacity (J) | 60000 |

| Power supply (KVA/ V/φ/HZ) | 100/380/ 3 /50HZ |

| Primary current (A) | 158 |

| Rated duty current (%) | 50 |

| Secondary empty voltage (V) | 30 |

| Throat depth (mm) | 280 |

| Rotary table diameter (mm) | 1100 |

| Oil cylinder diameter (mm) | 80 |

| Oil cylinder stroke (mm) | 150 |

| Electrode Dimensions (mm) | φ30×30 |

| Workpiece Dimensions (mm) | 20X150X220 |

| Welding speed m/min (s/piece)(time/s) | 9s/piece |

| Max. working pressure (kgf ) | 12000 |

| Compressed air pressure (MPa) | 0.6~0.7 |

| Cooling water consumption (L/MIN) | 12 |

| Driving motor power (KW) | 0.75 |

| Primary cable specification (MM2) | 3*35+2*16 |

Feature of car seat recliner welding machine

1. The Heron car seat recliner welding machine is equipped with a 60000J medium voltage capacitor discharge welding system.

2. The welding system also features an indexing turnplate with six stations.

3. Each machine supports an online input workpiece code.

Introduction of car seat recliner welding machine

The car seat recliner welding machine was specially designed for the welding of car seat components on a mass scale. Car seat recliner manufacturing machinery features German Glamtronic high voltage capacitor discharge welding technology. We can achieve the same welding effects with our medium voltage capacitor discharge welding machine. This minimizes energy consumption and improves production efficiency.