Products

Quick Links

Contact Us

Heron Intelligent Equipment Co., Ltd.

No.63 Xin Yi Road, Taiping Town, Conghua District ,Guangzhou

Christina Liu

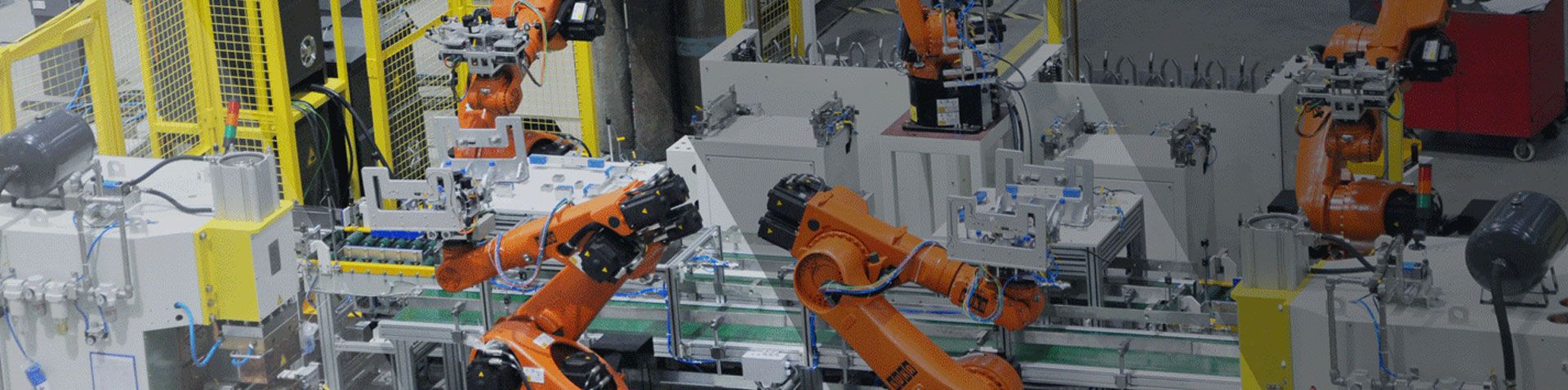

Heron provides manufacturers with auto parts welding machines that include a wide range of specialized welding equipment. Some of these products include spot and projection welding machines, recliner welding machines, nut welding equipment, car door welding machines, and more.