Products

Quick Links

Contact Us

Heron Intelligent Equipment Co., Ltd.

No.63 Xin Yi Road, Taiping Town, Conghua District ,Guangzhou

Christina Liu

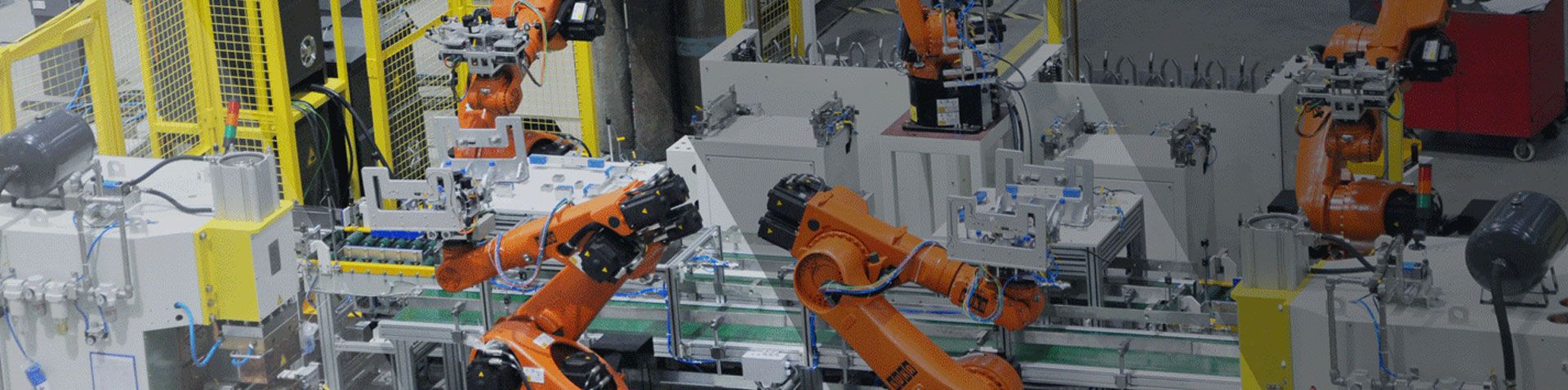

Heron provides motor manufacturers with high quality resistance welding machines for the production of their engine motors and alternators. The car alternator welders and engine motor welding machines are carefully designed to optimize production effectiveness and efficiency.