| Item | Height | Length | Width |

| Size | 2450 | 1840 | 1390 |

| Item | Parameter |

| Rated capacity (KVA) | 330 |

| Power supply (V/φ/HZ) | 380/ 3 /50HZ |

| Primary current (A) | 240 |

| Rated duty cycle (%) | 20 |

| Secondary empty voltage (V) | 13 |

| Throat depth (mm) | 290 |

| Arm gap (mm) | 490 |

| Cylinder stroke(mm) | 150 |

| Electrode Dimensions (mm) | φ30X60 |

| Workpiece Dimensions (mm) | φ30X30 |

| Welding speed m/min (s/piece)(time/s) | 4s/piece |

| Max. working pressure (kgf) | 2000 |

| Compressed air pressure (MPa) | 0.6~0.7 |

| Cooling water consumption (L/MIN) | 12 |

| Compressed servo motor power (KW) | 3.5 |

| Primary cable specification (MM2) | 3*50+2*16 |

| Max. Short Circuit Current of transformer (A) | 58000 |

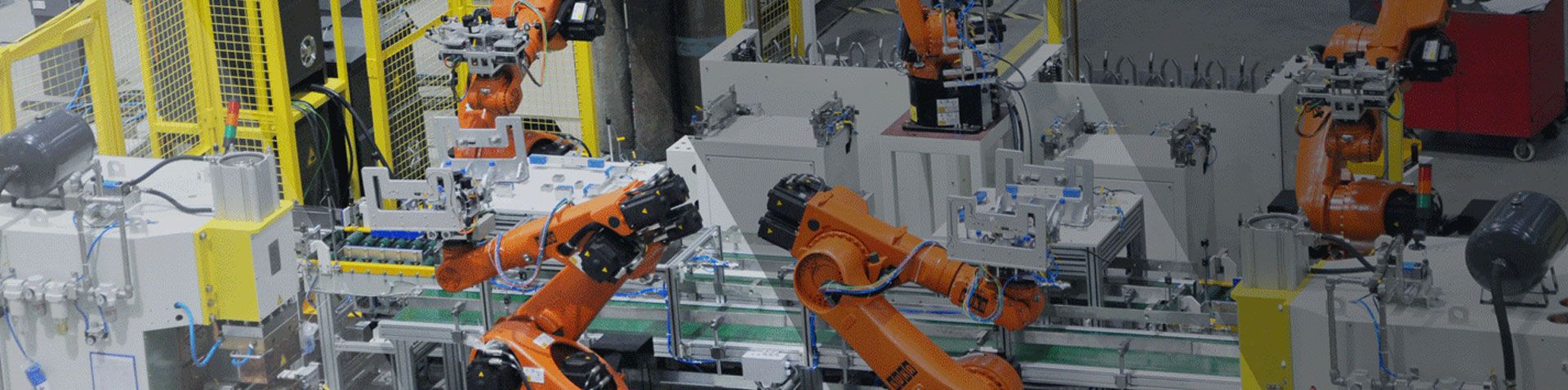

Feature of automatic welding machine for car wheel fastener

1. The automatic welding machine for car wheel fastener comes installed with a 330KVA Heron medium frequency DC power supply.

2. The welding system is outfitted with dual automatic loading systems.

3. The welding machine is equipped with a servo driven electric cylinder compression system.

4. Comes with a complete automatic assembly fixture system.

Introduction

The automatic welding machine for car wheel fastener is constructed for the head welding of car wheel nuts and it is outfitted with a 440KVA Heron medium frequency DC power supply. It is also outfitted with a dual automatic loading system and an automatic assembly fixture system. The welding system is designed to replace traditional manual welding processes and improve safety and maximize efficiency.