Products

Quick Links

Contact Us

Heron Intelligent Equipment Co., Ltd.

No.63 Xin Yi Road, Taiping Town, Conghua District ,Guangzhou

Christina Liu

Application

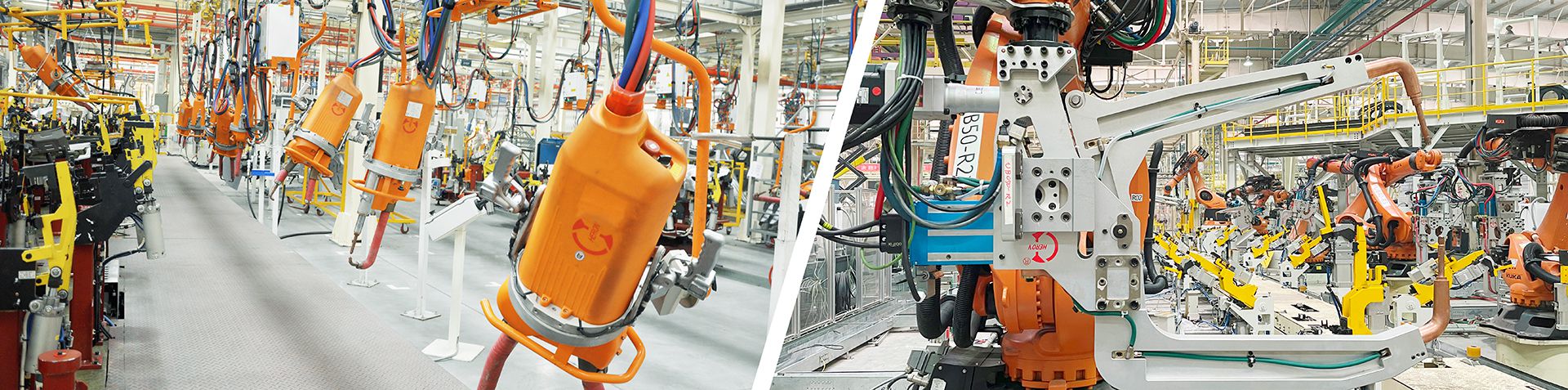

Robotic spot welding guns are primarily used for spot welding processes on the production line for auto body and cabinets.

| Model No | ||||

| Gross Weight(Kg) | 115 | 95.5 | 104 | 113.2 |

| Rated Capacity Of Transformer(KVA) | 75 | 110 | 110 | 110 |

| Arm Size(mm) | 70*262 | 52*320 | 110*280 | 579*542 |

| L*H*W (mm) | 967*633*423 | 1056*530*310 | 1031*530*3020 | 1376*834*406 |

| Max. Short Circuit Current(KA) | 20 | 24 | 24 | 24 |

| Max Stroke(mm) | 105 | 131 | 78 | 120 |

| Max Electrode Force(N) | 4400 | 4500 | 4400 | 4000 |

| Arm Deflection(mm) | 1.35 | ≤1.5 | ≤1.5 | ≤1.5 |

| Electrode Off Centre(mm) | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Center OF Gravity(X/Y/Z,cm) | 1.4/2/40.9 | 2.2/0.9/46.7 | 2.5/0.1/47.1 | 29.7/1/437.9 |

| Arm Material | Copper | Copper Bar | Copper | Aviation aluminum |

| Connecting Way With Robot | Top,Bottom,Left,Right,Rear | |||

| Servo Motor | Apply to all Robot Brands and Can be integrated with EXLAR | |||

| Model No | ||||

| Gross Weight(Kg) | 95.5 | 119 | 113.2 | 140 |

| Rated Capacity Of Transformer(KVA) | 75 | 110 | 110 | 110 |

| Arm Size(mm) | 384*160 | 284*125 | 242*300 | 815*250 |

| L*H*W (mm) | 1161*532*302 | 1050*531*190 | 1121*537*302 | 1400*825*190 |

| Max. Short Circuit Current(KA) | 20 | 24 | 24 | 24 |

| Max Stroke(mm) | 179 | 139 | 120 | 300 |

| Max Electrode Force(N) | 3900 | 4400 | 5000 | 4000 |

| Arm Deflection(mm) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Electrode Off Centre(mm) | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Center OF Gravity(X/Y/Z,cm) | 0.3/0.1/52.7 | 2.3/0.1/47.6 | 5.6/0.1/48.4 | 3/1.1/56.7 |

| Arm Material | Aviation aluminum | Aviation aluminum | Aviation aluminum | Aviation aluminum |

| Connecting Way With Robot | Top, Bottom, Left, Right, Rear | |||

| Servo Motor | Apply to all Robot Brands and Can be integrated with EXLAR | |||

Heron is engaged in making resistance welding system, is an experienced robotic spot welding gun manufacturer and welding solution provider. Since 1997 we have been offering wide range of AC resistance spot welders, DC resistance seam welders, MFDC resistance projection welding machines and robotic welding system for global customers.